.png?format=1500w)

[ad_1]

America’s provide chain infrastructure has been confronted with unprecedented disruptions and file delays over the previous 12 months. On this article, we’ll map out the steps of the availability chain, its present roadblocks, and its impacts on the tabletop gaming {industry} in addition to the American economic system as an entire.

We begin this deep dive off with some lighthearted Spiderman humor that precisely captures the blame recreation that every step of the availability chain is taking part in. We imagine it’s an essential subject to discover because it is among the largest challenges that each one companies, and particularly indie board recreation builders, are going through in the present day. This report’s purpose is to attempt to unravel an immeasurably complicated system right into a considerably digestible understanding. Our hope is that we can provide clients and creators slightly extra readability on the present provide chain disaster as an entire. This will help every occasion handle expectations, cut back friction, and lean right into a solution-first mindset to sort out an issue that affects practically each {industry}.

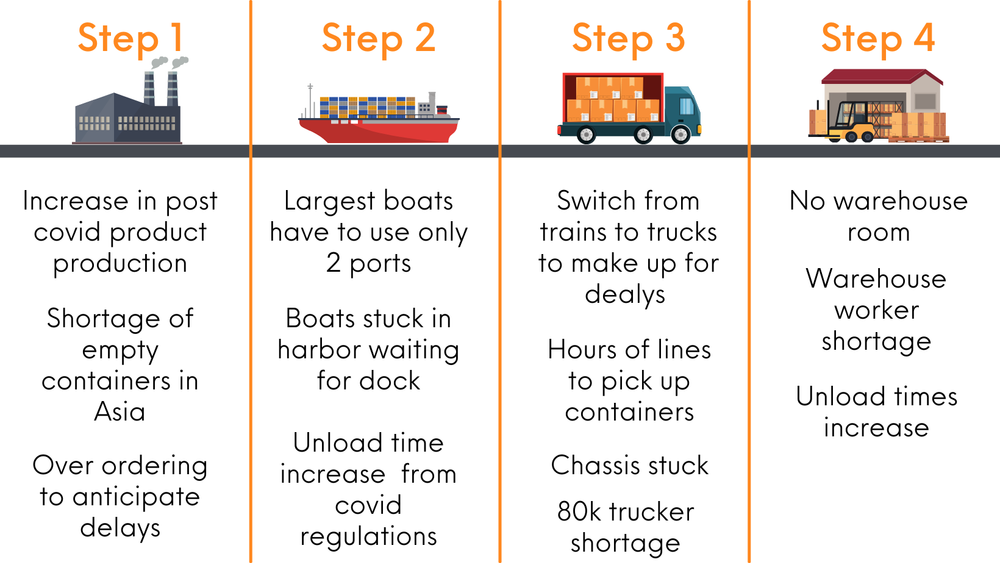

To higher arrange all of the breakdowns within the system, we will probably be separating the journey of a board recreation (or any product) into 4 foremost sections: Asian Factories, US Ports, Interstate Transport, and Warehouses/ Companies. These 4 steps create a large loop and every has loops inside loops. We’ll then look at how every of those steps impacts the board recreation market particularly in addition to future problems to contemplate. To all our non-American readers, don’t click on out! Whereas we would not be straight inspecting each worldwide provide chain problem, we promise this will probably be just like your state of affairs, as, sadly, a lot of your woes are being brought on by the USA (I do know stunning).

The Most Excessive-Degree Abstract Potential

Step 1- Asian Factories

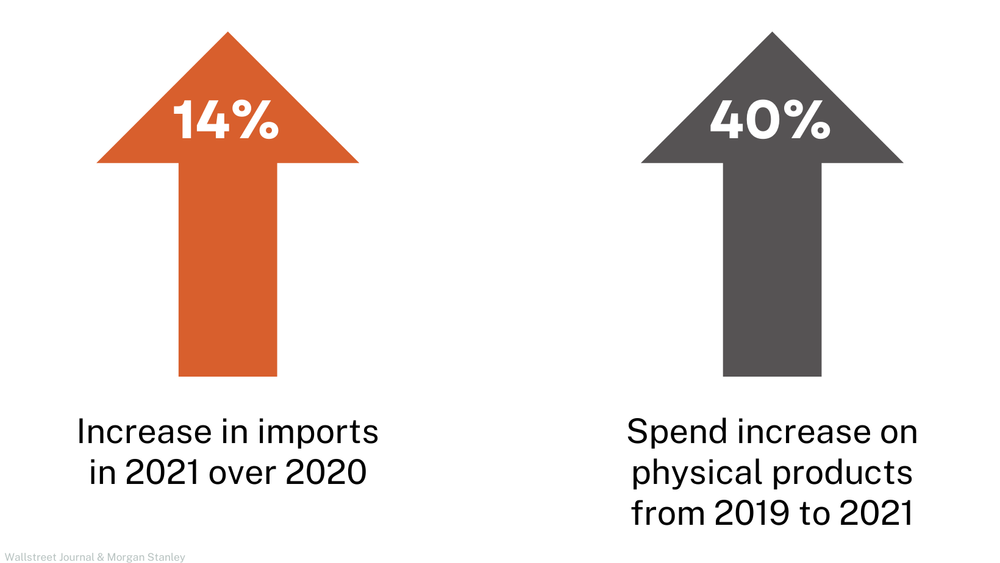

Unsurprisingly, we are able to hint most of the present challenges again to the one and solely Coronavirus. When folks had been unable to depart the home throughout the pandemic, spending habits switched from companies to bodily merchandise. After factories reopened from the shutdowns, they needed to course of each the backlog of orders in addition to new orders. The Wall Avenue Journal reported a 14% enhance in imports in 2021 over 2020 and Morgan Stanley documented that, “spending on durables in October 2021 was 40% increased than it was in October 2019.”

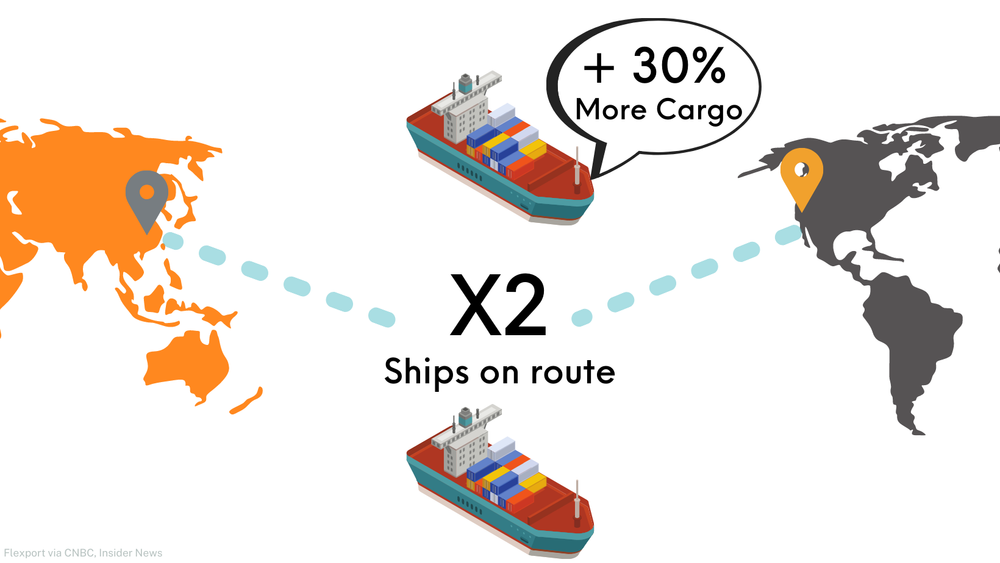

Seeing the uptick in demand and realizing the inevitable delays, firms exacerbated the issue by preemptively inserting larger-sized orders earlier within the 12 months. This put a brand new, huge stress on an already unbalanced system. Insider Information documented that the primary 9 months of 2021 alone noticed a rise in cargo quantity by 30%. In the meantime, Flexport by way of CNBC, revealed that transit from Asia to North America has doubled since 2020.

Rolling into 2021 and 2022, the variety of items produced has continued to exceed the variety of obtainable empty containers in Asia. Whereas there are a number of contributing components, this explicit concern additionally started at the beginning of 2020 throughout the months-long, covid shutdown of Asain factories. Anticipating monetary losses from a possible covid-caused recession, many ocean carriers determined to cancel the cargo of empty containers in America again to Asia, based on McKinsey’s newest logistics report. As factories reopened, ready-to-ship merchandise started to pile up and not using a technique to get them to the patron.

We also needs to look at an extra complicating issue: import vs export charges. People import at far larger charges than they export. This ends in much more empty containers being caught stateside. The opposite main roadblock is the dearth of area on the ships themselves. The elevated import demand and California port delays (extra on this later) add one other layer to an already costly drawback.

So what does all this imply for companies? Merely put, large spikes in transport container prices. In response to a 60 Minutes section from December of 2021, commonplace containers that value $2,000 pre-pandemic now have a price ticket of as much as $20,000! A fast terminology lesson, transport containers usually fall into considered one of two classes: TEUs aka Twenty-foot Equal Unit ({industry} commonplace) and FEUs or a Forty-foot Equal Unit. Whereas $20,000 a container could also be on the excessive finish, we are able to monitor the general world rise of freight charges on Freightos Knowledge’s International Container Index.

Step 2- USA Ports

For those who thought the challenges on the manufacturing aspect of this had been unhealthy, simply await the largest bottleneck, American Ports. The docking points are a lethal recipe of 1 half enhance in imports, one half labor shortages, and one half outdated cargo/ empty items not transferring out of the way in which.

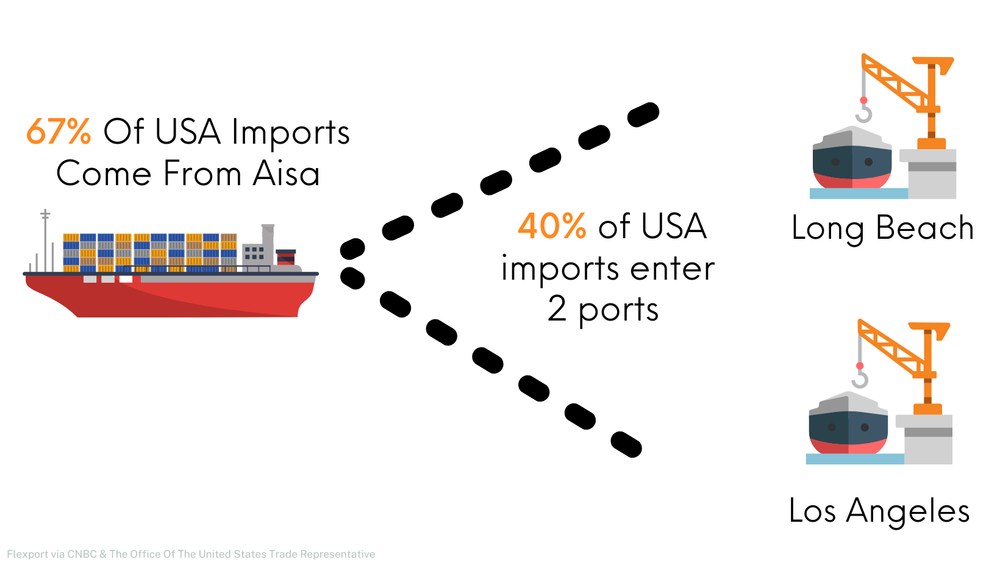

In response to Flexport by way of CNBC, transport transit from Asia to North America has doubled since 2020 main to 2 occasions the quantity of vessels being utilized. In 2018 The Workplace Of America Commerce Consultant final revealed that 67% of US imports come from the APEC area (Asian Pacific). CNBC factors to a different complicating issue, the biggest vessels, subsequently essentially the most environment friendly and inexpensive, are unable to suit by the Panama canal. This contributes to 40% of imports coming by two California ports: Los Angeles and Lengthy Seaside. It’s right here we encounter our subsequent massive bottleneck.

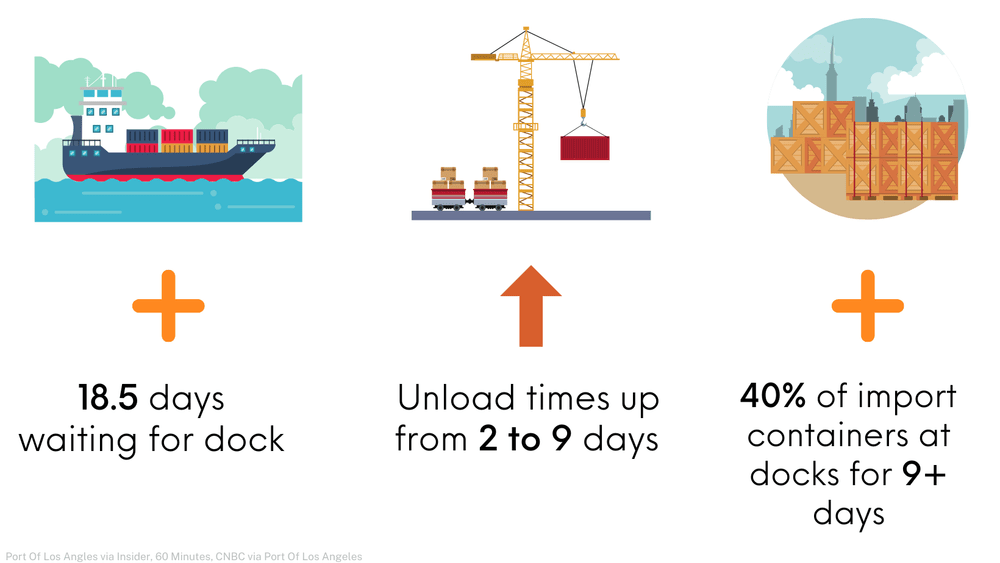

In November of 2021, the Port of Los Angles, Through CNBC, famous that roughly 11.5% of the worldwide vessels had been “offline” because of being caught in a queue simply to get right into a dock. In that very same month, the Port Of Los Angles by way of Insider revealed that ships had been ready a mean of 18.5 days to come back into the docks. In February 2022, CNBC confirmed that there are nonetheless over 90 boats unable to enter the Port of Los Angeles.

As soon as a vessel pulls up it must be unloaded. The December 60 Minutes particular revealed that the common unload time went from 2 days to as much as 9 days to unload only one boat. Covid rules performed a serious function within the elevated unload occasions. At the same time as just lately as January of 2022, Port of Los Angeles said that round 10% of dock workers contracted covid and had been unable to work. This decelerate compounds the shortages brought on by the “The Nice Resignation”. The Pew Analysis Middle said that the nationwide “give up charge” reached a 20-year excessive final November. In the meantime, Fortune Journal quoted the Bureau of Labor Statistics and famous that the commerce, transportation, and utility sector noticed the second highest give up charge.

The ultimate complicating issue for American Ports is the truth that all these extra cargo ships face a scarcity of area to retailer the brand new product as soon as it arrives. The Port of Los Angeles by way of CNBC reported that in October of 2021 40% of all imports had been left on the ports for greater than 9 days. An additional 69,000 empty TEUs had been taking on useful area in February of 2022. Earlier than the pandemic, most cargo sat on the ports for an common most of 2-4 days (relying on the supply technique). This stagnation led the ports of Lengthy Seaside and Los Angeles to cost firms charges of $100 a day for any container not picked up inside 9 days of its arrival. Regardless of all of those points, you will need to level out latest progress. For instance, as of January of 2022, the Port of Los Angeles and Lengthy Seaside recorded a mixed discount of 62% of “getting older cargo” at their respective places.

Step 3- Interstate Transport

Vehicles or trains? There isn’t a proper reply, as you’re positive to have delays and markups with each strategies. In a non-crisis atmosphere transporting items by prepare is each cheaper and higher for the atmosphere. TEUs might be loaded onto the fright trains and transport massive portions of things to a number of central hubs, in the course of America. From a centrally positioned rail yard, an organization’s merchandise can then be divided into smaller shipments to particular warehouses/ achievement facilities over a lot shorter distances. For a real deep dive into this course of, take a look at this story within the Wall Avenue Journal! Lengthy story brief, in the summertime of 2021, railyards reached their storage capacities and had been unable to simply accept any extra containers. On high of that, outdated product arrivals obtained caught beneath new items, leaving companies with no technique of accessing their items. 60 Minutes talked with one enterprise proprietor who had been receiving charges for not choosing up the cargo that he was unable to entry. Unfair conditions like this have began to drive folks away from the railway possibility. In an try to attempt to make up time from the delays from the cargo ships, firms have regarded to the sooner, costlier, and fewer environment friendly different of trucking.

Whereas switching intercontinental transport to vehicles might sound like an costly however higher possibility, the fact is a bit grimmer. A Forbes article from January 2022 documented that 71% of the US economic system is moved by truckers. The Wall Avenue Journal connects a 130% enhance of vehicles on the most well-liked route of LA to Chicago, with a 59% enhance within the value of transferring items alongside this similar route.

This similar Forbes piece additionally reveals that the pre-pandemic turnover charge for truckers was already terribly excessive at 94%. In December of 2021, the American Trucking Affiliation by way of Insider Information revealed information that said that there was a scarcity of 80,000 truck drivers. This trucker scarcity is yet one more results of the “Nice Resignation”. Going again to the Pew Analysis Middle, the highest 3 causes folks disclosed as their motive for quitting had been: low pay, not sufficient career-advancing alternatives, and feeling disrespected. Truck drivers actually fall into the primary class based mostly on how the compensation system is at the moment structured. Somewhat than being paid by the hour, drivers are paid by the load. Moreover, Insider Information detailed how, with too many TEUs sitting on the port, drivers can wait as much as 8 hours in traces over 5 miles lengthy to choose up their subsequent supply with none extra compensation.

One more complication lies within the continuously altering rules round what items can and can’t be returned. As soon as once more highlighted within the 60 Minutes section, each day modifications to those tips imply that truckers with an empty container of a sure colour are unable to return it to the port. This could change into a large drawback given {that a} driver is unable to choose up a full container with out first returning an empty one.

We are able to look again to that very same 60 Minutes piece and be taught that the pickup system itself has deep flaws. From the port’s perspective, they had been seeing truckers miss their cargo pickups at a charge of round 30-50%. Nevertheless, there’s a main sticking level: the scarcity of only one piece of apparatus known as a chassis. Freight Proper defines this as, “a particular trailer or attachment that enables ocean containers to be transported by way of truck. A chassis is required for shipments transitioning from sea to street…Chassis work by becoming snugly across the container, holding it from transferring round throughout transport…”. So the place are all of the lacking chassis you may ask? Nicely, they’re caught within the shipyards beneath empty containers ready to be shipped again abroad. And with no room for both empty or full containers, together with the mandatory gear to maneuver these things being caught, we discover ourselves at yet one more Catch 22.

Step 4- Warehouses & Companies

The ultimate part of the availability chain, so far as this text is worried, are warehouses. The Wall Avenue Journal wrote that unload occasions at warehouses have elevated by 30%. There are two foremost causes for this: not sufficient labor and never sufficient area.

Whereas delays could also be holding up inventory overseas, when the objects lastly arrive many firms have ordered far past their amenities’ capacities. In December of 2021, Insider Information by way of CBRE recorded warehouses close to LA and Lengthy seaside solely had 1% of their warehouse areas open. Nationwide, warehouses had been observing a 3.6% common, emptiness charge. That is the bottom capability since 2002.

We revisit the “Nice Resignation” to handle the employee scarcity right here. Warehouse jobs are sometimes seasonal, at odd hours, in loud environments, and troublesome on the physique. Low pay, poor advantages, and coaching occasions make for one more logistical nightmare on the closing step of the availability chain. Forbes investigated this drawback again in October of 2021 and recorded that the Division of Labor has listed 490,000 {industry} openings in July of 2021 in each the warehouse and trucking industries (the Division of Labor doesn’t separate these industries). As you noticed earlier, the trucking {industry} confirmed a necessity for 80,000 truckers so do the maths and you will notice warehouses are additionally in dire want of workers.

Board Recreation Trade Deep Dive

The board recreation {industry} is going through delays and extra bills from all of the aforementioned provide chain disruptions. Nevertheless, the {industry} on an entire, and particularly indie recreation builders, are experiencing points at a good increased charge. To get a greater deal with on this, I can not advocate sufficient the Podcast Ludology episode titled “GameTek 255.5 – International Logistics Woes”. In it, the 2 hosts, Geoff Engelstein & Gil Hova, discuss to a logistics specialist, Justin Bergeron of ARC International Logistics, who works with a whole lot of board recreation firms and is aware of the ins and outs of this market. This episode got here out in August of 2021 nevertheless it makes Justin’s predictions of what has continued to occur that rather more spectacular. So, with this in thoughts, let’s flip to a few the hurdles that intensify the results of provide mismanagement for the tabletop gaming {industry} particularly.

-

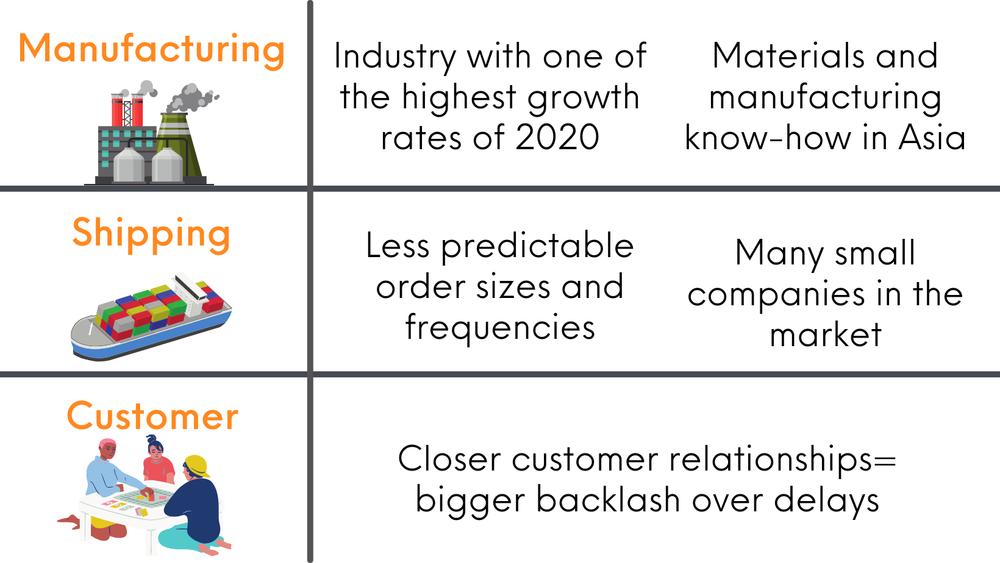

Board recreation firms noticed a number of the largest progress charges out of any {industry} ensuing from covid. We are able to look again at final 12 months’s covid market affect article and see that Technavio reported a 25% progress charge for the {industry} and Kickstarter noticed a 33% funding enhance within the tabletop gaming section. So proper off the bat, board recreation builders noticed an extra demand increased than many different industries.

-

Time Journal has an incredible article with a number of interviews that particulars how board video games make the most of many uncooked supplies which can be sourced in Asia. This, together with cheaper labor, has led to quite a few factories in locations like China changing into the perfect spot to provide video games. The Ludology podcast additionally will get into how Chinese language producers permit for way more customization in recreation elements in comparison with their Western counterparts. So, economically and skill-wise Asia has change into the one choice to manufacture video games.

-

The board recreation market is fairly fragmented. Whereas there are huge gamers like Hasbro, Kosmos, and many others, a good portion of the market is split between many small, indie builders. Whereas this makes for a unbelievable diversification of merchandise and fantastic alternatives for small enterprise homeowners, it additionally leaves the small recreation builders disproportionately susceptible to the massive transport company’s charge hikes. The bigger recreation builders have the flexibility to unfold their bills throughout huge shipments with different merchandise. They’ll even leverage retailers like Walmart and Amazon to assist cut back prices and delays.

-

On the Ludology podcast, they focus on how one of many extra distinctive challenges going through the tabletop gaming {industry} is order dimension. The character of Kickstarters in addition to small companies not desirous to incur the expense of holding massive portions of unsold inventory, oftentimes leads indie builders to order smaller portions at much less predictable intervals. Small order sizes don’t take up a complete TEU, leaving small recreation firms reliant on one other enterprise to separate the transport charges with them.

-

The Ludology podcast additionally particulars how board video games, and all their many items, have a a lot increased density to quantity ratio. This makes utilizing freighters considerably less expensive as they cost by the area the products take up in a TEU. Alternatively, this makes alternate transportation strategies resembling air fright prohibitively dearer since they cost by a product’s precise weight.

-

Smaller firms, particularly these using crowdfunding, have nearer “relationships” with their clients than the common firm. So when raised costs change into needed, board recreation clients really feel it extra personally, as in the event that they had been “an element” of the launch expertise and had been “promised a value”. The backlash might be punitively unfair to small companies. This is among the foremost causes we wrote this text, in an try to lift consciousness among the many normal inhabitants of simply how complicated this transport disaster is and the way disproportionately affected small indie video games really feel its damaging impacts.

Wanting Ahead

The ethical of this provide chain horror story is that dependence on overseas manufacturing has lastly caught up with People. The pendulum should swing again to native manufacturing unit manufacturing, more than likely by leveraging new automation expertise. Each European and Asian international locations are already utilizing considerably superior automation processes at their ports whereas the USA sits a long time behind. Even with authorities intervention, Insider Information revealed that specialists are predicting that transport prices will proceed to rise effectively into 2023.

Overseas coverage will even play an growing function within the close to future. There’s uncertainty about how China’s “zero covid coverage” will play out going ahead. This month China halted manufacturing however then walked it again per week later based on Bloomberg.com. This flip-flopping is dovetailing with the already tense relationships between these two international locations from the “Commerce Struggle”. Additionally, with the potential of China backing Russia and subsequently falling beneath the present Russian commerce sanctions, the Japanese European disaster has the potential to devastate the availability chain much more than it at the moment has. The Harvard Bussiness Overview informs us that of of the primary repercussions will probably be skyrocketing petroleum costs rippling by the already exorbitant transportation charges. Moreover, some industries had been depending on Russia and Ukraine for uncooked supplies and very important elements. Wanting ahead, locations like Texas have gotten the front-runner because the epicenter of the subsequent era of American manufacturing.

To search out near-term options, it’s time to take a web page from a number of the world’s largest companies. CNBC particulars how Amazon has fared comparatively unscathed throughout all these disruptions because of proudly owning and working nearly all of its provide chain. They ramped up making their very own TEUs, employed their very own truck drivers, acquired smaller cargo vessels that may unload at smaller and subsequently much less congested ports, and even invested in their very own air freight fleet. In one other instance, their opponents like Walmart and House Depot determined to place apart their competing market overlap and labored with one another to assist cut back stalls and value raises by sharing the area and value of each the containers and vehicles. Maybe it’s time for indie board recreation builders to open up extra traces of communication with one another and coordinate their manufacturing and transport to most effectively get their items stateside.

Closing Ideas

Whereas the world and America tries to determine their multi-industry provide chain issues, Tabletop Simulator is at all times right here as an incredible digital different, particularly for small indie firms. To assist unfold this useful resource and get the phrase out about up-and-coming new video games, the TTS Weblog invitations smaller recreation firms and board recreation fans alike to take a look at our Tabletop Talks and Playtesting Promotion Sequence. This can be a nice method to discover thrilling new video games that you may check out on Tabletop Simulator whereas additionally supporting these firms’ numerous campaigns. If you’re keen on having your recreation featured you may fill this way out right here! We hope this text was useful in breaking down a really difficult system and that the common board recreation shopper can come away from studying this with slightly extra sympathy for the delays from the indie board recreation builders we love and cherish.

Please make the most of our sources to be taught extra from specialists as we are able to promise you, there may be a lot extra to find out about this attention-grabbing and essential topic! Click on right here to get an organized listing of all our unbelievable sources and revel in happening the logistics rabbit gap!

Tell us your ideas!

What have your experiences been throughout the transport disaster? Are you a developer attempting to navigate delays and pricing? Are you a annoyed buyer ready on your already paid-for recreation? Do you might have any inventive options? Share your opinions within the feedback under!

Subscribe to the Tabletop Simulator Weblog!

Thanks for signing as much as the Tabletop Simulator Weblog!

[ad_2]